A Primer on 3D Printing

This is a TED talk by Lisa Harouni that gives a great overview of 3D printing. This video gives a great overview of 3D printing and some of the possibilities that exists.

Additive Manufacturing

3D Printing is also called "additive manufacturing". Additive manufacturing is when a raw material is placed, over time, one layer at a time, to build up a three-dimensional object.

vs. Subtractive Manufacturing

The opposite of additive manufacturing is subtractive manufacturing where material is cut away from a solid material until the object that is desired is created. Wood carving is an easy example of subtractive manufacturing.

3D Printing Demo

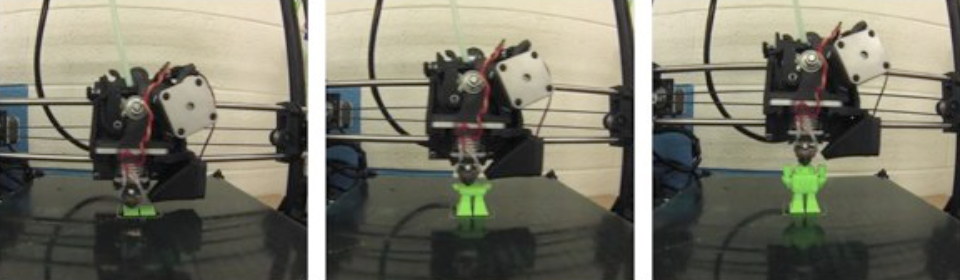

This is a time-lapse video of a 3D printed robot.

The video demonstrates the additive manufacturing process where material is placed one layer at a time to create a three-dimensional object.

The object printed in the video is the Maker Faire Robot. You can download the robot from Thingiverse here: http://www.thingiverse.com/thing:40212

The object printed in the video is the Maker Faire Robot. You can download the robot from Thingiverse here: http://www.thingiverse.com/thing:40212

What can 3D printing do?

Small Batch Manufacturing

3D printing is great for "small batch" manufacturing or "one off" manufacturing where you only need a very limited number of objects created.

Personalized/Customized Objects

Mr. P's Class is a small classroom only a handful of students a class. If we wanted to have a custom created that had our school logo on them, it could be quite expensive using traditional manufacturing techniques using plastic injection molding or cutting them from metal but using 3D printing, we can easily create custom things and print them per person:

3D printing is great for "small batch" manufacturing or "one off" manufacturing where you only need a very limited number of objects created.

Personalized/Customized Objects

Mr. P's Class is a small classroom only a handful of students a class. If we wanted to have a custom created that had our school logo on them, it could be quite expensive using traditional manufacturing techniques using plastic injection molding or cutting them from metal but using 3D printing, we can easily create custom things and print them per person:

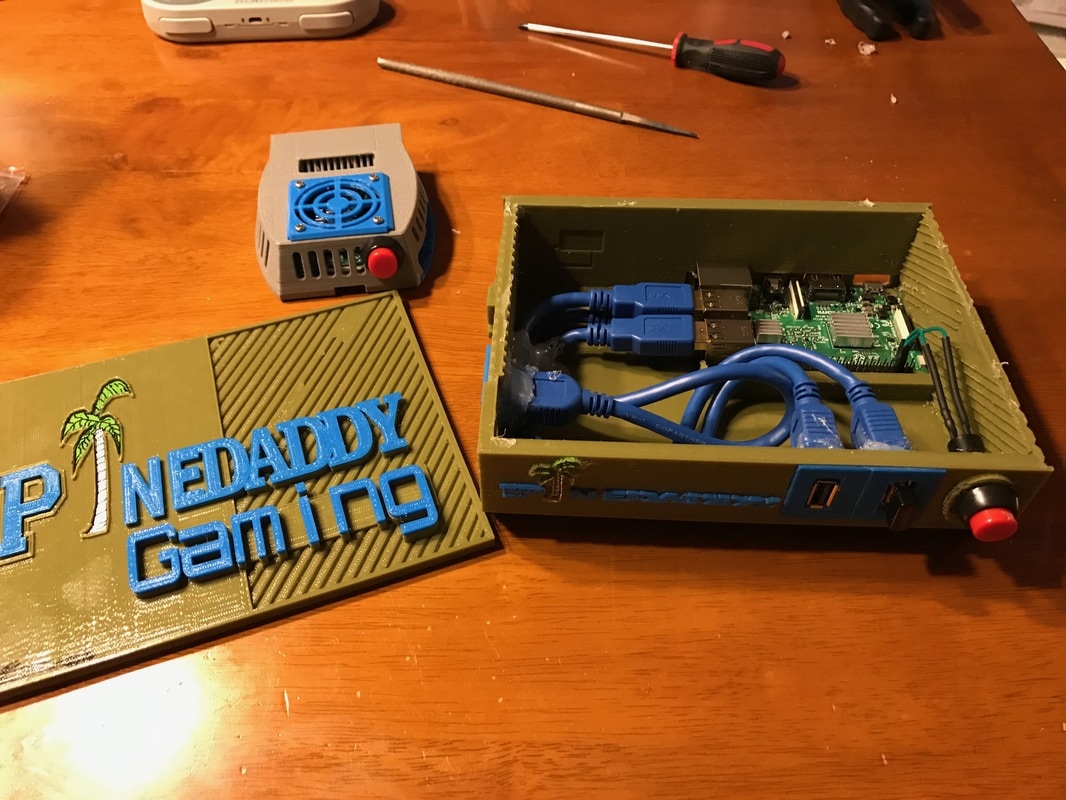

PrototypesIn addition to personalized objects, you can create prototypes for different projects. The relatively fast turn around of 3D printing allows you to try different approaches or make small tweaks to product designs without a huge investment in time or money.

Below, I demonstrate a few different Rasberry Pi Case prototypes created using 3D printing. Each represents a minor change that I tried with the design. Thanks to 3D printing, I was able to explore different designs in the course of a few days rather than months.

3D Printing as Mass Manufacturing

Currently, 3D printing just can't keep up with the speed or quality of current mass manufacturing trends. This may all change one day but for now, it just isn't a reality. Some companies have experimented with rooms or warehouses filled with 3D printers but the maintenance and management of the devices proved to be too expensive as demand grew.

Benefits of 3D Printing

Low Commitment

In the past, if you wanted to test or sell a product, you had to get enough orders ahead of time before you could start actually manufacturing. With 3D printing, the commitment is very low and you can print a few items up front and then try to sell them.

Print On Demand

T-Shirts and books are a great example of industries that have experimented with "print on demand" services and have found a role for these services. It used to be that you if you designed a t-shirt that you wanted to sell, you had to order a bunch of shirts up front and have them printed. You could try to guess what sizes would be in most demand but ultimately, you always ended up with some shirts left over that you just couldn't sell sitting in a box in a closet or in storage. With print-on-demand services, you print a shirt when a customer orders one and have it delivered directly to them.

3D Printing offers the same ability to creators of physical objects. Sites like www.shapeways.com allow you to setup a shop and sell your 3D designs. They will print them for you and ship them to your customers.

Affordable

The prices of 3D Printers are dropping as their popularity increases and people find new ways to create them. It is now fairly typical to purchase your first 3D printer for less than $1,000 with some models being under $500. They are also starting to be sold in more main stream places such as Staples and MicroCenter.

Less Waste

Additive manufacturing produces much less waste compared to subtractive manufacturing because only the material you need to create the object is added versus unused material being removed.

Less Mess

There is also less mess with additive manufacturing. When you are subtracting material from an object, it needs to go somewhere and so you end up with a lot of saw dust or metal shavings all over.

Low Commitment

In the past, if you wanted to test or sell a product, you had to get enough orders ahead of time before you could start actually manufacturing. With 3D printing, the commitment is very low and you can print a few items up front and then try to sell them.

Print On Demand

T-Shirts and books are a great example of industries that have experimented with "print on demand" services and have found a role for these services. It used to be that you if you designed a t-shirt that you wanted to sell, you had to order a bunch of shirts up front and have them printed. You could try to guess what sizes would be in most demand but ultimately, you always ended up with some shirts left over that you just couldn't sell sitting in a box in a closet or in storage. With print-on-demand services, you print a shirt when a customer orders one and have it delivered directly to them.

3D Printing offers the same ability to creators of physical objects. Sites like www.shapeways.com allow you to setup a shop and sell your 3D designs. They will print them for you and ship them to your customers.

Affordable

The prices of 3D Printers are dropping as their popularity increases and people find new ways to create them. It is now fairly typical to purchase your first 3D printer for less than $1,000 with some models being under $500. They are also starting to be sold in more main stream places such as Staples and MicroCenter.

Less Waste

Additive manufacturing produces much less waste compared to subtractive manufacturing because only the material you need to create the object is added versus unused material being removed.

Less Mess

There is also less mess with additive manufacturing. When you are subtracting material from an object, it needs to go somewhere and so you end up with a lot of saw dust or metal shavings all over.